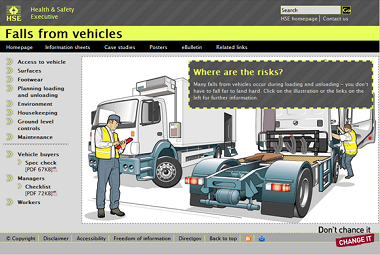

Approximately 2000 workers are seriously injured and on average 5 lose their lives across all industries every year as a result of falling from a vehicle. The construction industry accounts for around 10% of these incidents.

For all other industries, approximately three-quarters of those injured are delivery drivers. However, in construction 70% of all falls from vehicle injuries occur to non-drivers i.e. those who are involved in unloading delivery vehicles.

These falls occur mostly when workers/operatives are loading or unloading and getting on or off the vehicle. Most of the vehicles involved are Flat Bed trailers

In the UK reinforcing industry, flat beds are often used to transport cut and bent reinforcing steel bars, welded fabric and prefabricated cages to site. Due to the wide array of shapes and sizes that a project can demand it is rare that full 25 Tonne loads are delivered. Part of the problem is ensuring that the load is safe to transport, part is making sure it can be unloaded without too much difficulty on site and part is to reduce the risk of cages being damaged en route. All this can cause loads to be as small as 3 or 4 Tonnes when transporting lightweight prefab cages making deliveries expensive and un-environmentally friendly.

What are “Safety Trailers”?

Safety Trailers were developed by the UK and Irish reinforcing steel fabrication company Midland Steel. They came about as the company needed a way to transport, safely, larger volumes of prefabricated cages of reinforcement whilst also providing a safer environment for their goods to be loaded and unloaded.

A “Safety Trailer” is a 6m x 2.9m x 1.35m high stillage (cradle) that is attached to a flatbed trailer via the Twist Locking systems used for containers. Two of these stillages can be placed end to end on a flatbed leaving a 1.3m wide access zone at the front of the trailer.

All Safety Trailers are the same size, but come in two variations.

The first is the 'Open Cradle Safety Trailer' which offers a robust side protection system, with each stillage made from steel square hollow section stanchions and cross members, making them perfect for bulky or long construction products and materials.

The second is the 'Closed Cradle Safety Trailer' which offers the same side protection but each stillage has steel mesh welded to the inside face and gated end section, making them perfect for a more diverse range of products and materials whilst providing delivery operatives with enhance anti-fall protection.

A flat-bed trailer can carry four of these cradles as they have been designed to stack one on top of the other. They are connected by corner spigots locating inside the square hollow section stanchions.

Once stacked, the top of the higher stillage represents the maximum transportable height for UK roads (4.51m) giving a great visual reference to ensure no load exceeds this height.

Following successful trials supplying material using these cradles, several main contractors have started to regard them as the industry best practice for delivery of certain construction products to site. Their site staff are the ones who christened them “safety trailers”.

"...several main contractors have started to regard them as the industry best practice.."

![]()